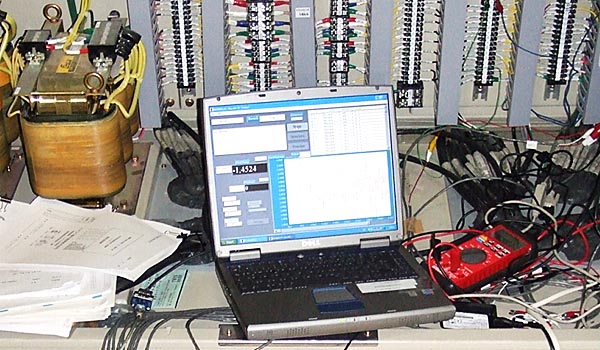

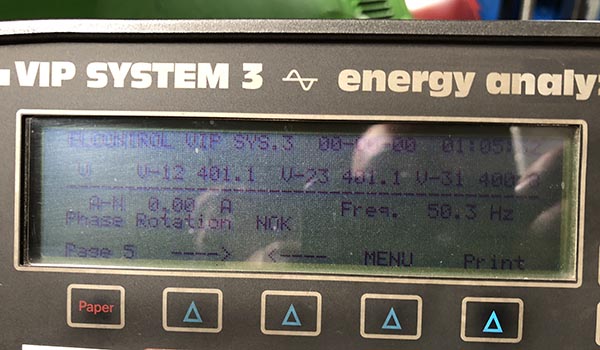

Using the most modern testing and measuring methods, we are able to quickly and clearly classify system errors and react accordingly. On the one hand we fall back on our well sorted spare parts stock and on the other hand on our short wire to the leading manufacturers of generators.

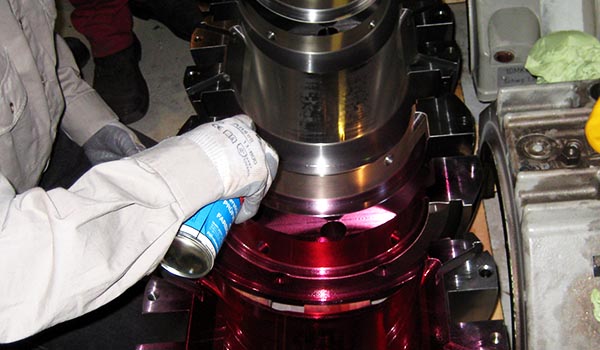

Maintenance errors often prove to be the cause of reduced downtimes. The problems occur insidiously and unfortunately all too often result in major repairs. That is why we offer you a comprehensive maintenance service in addition to the elimination of acute malfunctions.